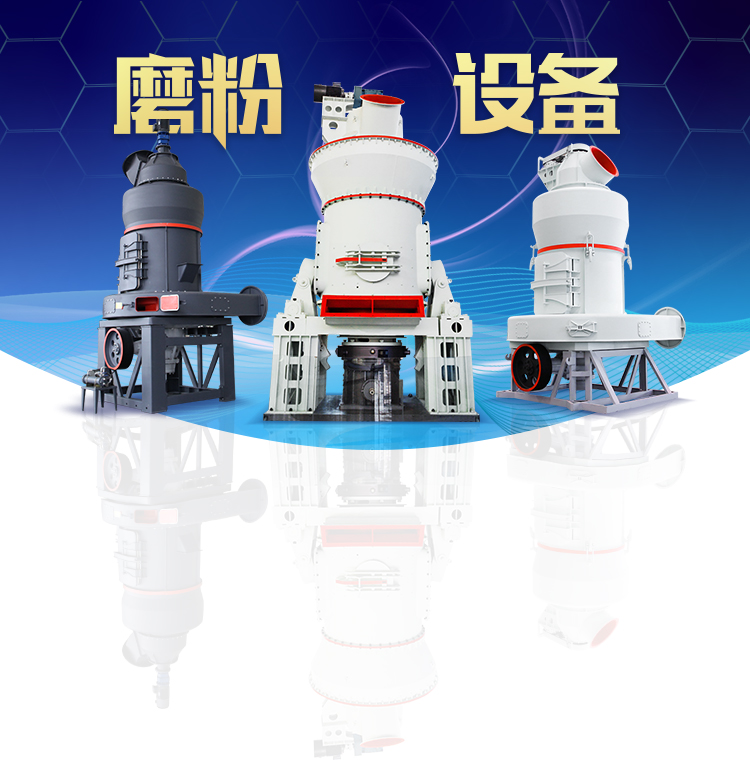

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Adjusting Size On Mining Cone Crushing Equment

.jpg)

Size reduction control in cone crushers ScienceDirect

2021年11月1日 This paper describes a novel size reduction control strategy for cone crushers to address this problem The proposed control strategy is based on selfoptimizing control structure (nearmaximum performance using constant setpoint) to ensure the desired degree of size 2025年3月17日 This paper describes a novel size reduction control strategy for cone crushers to address this problem The proposed control strategy is based on selfoptimizing control Size reduction control in cone crushers Tampere 2023年2月24日 Proper adjustment of a cone crusher is crucial for its efficient operation and to ensure that it produces the desired product size In this article, we will provide an overview of the steps involved in adjusting a cone crusher How to Adjust a Cone Crusher: A StepbyStep 2009年10月1日 Combining the empirical model for predicting particle shape with the size distribution model, a flakiness prediction model is proposed With the size reduction model and Cone crusher chamber optimization using multiple constraintsAdjusting a cone crusher involves several steps, ensuring the machine runs efficiently and produces the desired product size Here's a general guide on how to proceed: Power Down: How to Adjust a Cone Crusher zenithmineral2021年8月15日 Large particles must be reduced to specific sizes to either comply with aggregate sizing regulations, or facilitate mineral liberation; therefore, in the aggregates and A review of modeling and control strategies for cone crushers

A Detailed Overview of Cone Crushers and What

How to Adjust a Cone Crusher; Cone Crusher Diagram; Choosing the Right Cone Crusher for Your Quarry and Mining Operations Cone crushers are among the most versatile and useful pieces of aggregate crushing equipment with many 2024年5月9日 Here are some tips on how to increase the capacity of a cone crusher: Optimize the feed material: The size and hardness of the feed material can have a significant impact on How to Increase the Capacity of Cone Crusher? CM Mining By operating the adjusting nuts, the crushing cone is sufficient or rises, causing the discharge port to become larger or smaller Of course, depending on the model, there may be other ways to adjust the machine’s discharge size, as Impact Crusher Capacity Improvement And Crushing Equipment; Mobile Crushing Plant; Grinding Equipment Gold Cyanidation Equipment; Dewatering Equipment; Belt Conveyor; Watch Videos adjusting size on larger capacity cone adjusting size on larger capacity cone crusher Videos Center2021年6月15日 Cone crusher is one of the mainstream crushing equipment in mining industry It is mainly used for medium or fine crushing for various kinds of raw materials The output size of cone crusher is determined by the distance between mantle and concave But many people don’t know much about the discharge adjustment dvice of cone crusher3 Types Of Discharge Adjustment Devices For Cone Crushers 2015年7月18日 Coarse crushing includes crushing operations discharging at sizes 4 to 6in or coarser; intermediate crushing comprises operations taking feeds 6 or 8in maximum and making products down to 1/2″ or 3/8″ Fine Rock Crushing Process in Mining 911Metallurgist

.jpg)

7 Differences Between Symons Cone Crusher And Hydraulic Cone

2025年1月7日 The gap needs to manually operate to adjust it, usually using a jack or other manual tools Hydraulic Cone Crusher: Use the hydraulic system to automatically adjust the crushing gap, which is easier to adjust without intervention Overload protection Symons Cone Crusher: Relying on mechanical spring to protect the overload If the crusher is 2025年1月16日 Cone Crusher Parts Jaw Crusher Parts Impact Crusher PartsHow Do You Adjust The Gap on A Cone Crusher? Xiangjian 2014年1月1日 Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation of rock materials Control systems for cone crusher settings are widely used to compensate for wear and to protect the machines The eccentric speed in a cone crusher affects the number of compressions the material is exposed to and thus the particle size distribution of Online Optimization of Crushing Stage Using Speed Regulation on Cone 2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly The Evolution of Crushing and Grinding: Changes in the MININGThe cone series crushers compress stone/rock mineral materials by squeezing force between the fixed shaft and moving shaft Change the least gap between the two crushing shafts of the Cone Crusher Mine Crushing 2023年12月1日 6 53 Cone crusher : With the rapid development of mining technology, the cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher and SIZE REDUCTION BY CRUSHING METHODS By

Constant Wear Criterion for Optimization of the

2024年1月15日 The crushing chamber of a cone crusher is composed of the mantle and concave The particles in the crushing chamber are crushed by the squeezing of the mantle and concave2023年5月29日 The Nordberg® HP Series™ for mining Metso's Nordberg HP Series cone crushers are ideal for many different mining applications In mines, cone crushers are typically needed for crushing to obtain the maximum size reduction ratio and they typically focus on producing material for the downstream processNordberg HP Series cone crushers – High performance 2025年1月14日 The cylinder is separated by the piston into A and B chambersThe HP cone crusher uses the hydraulic system to adjust the breaker gape size, the hydraulic system can HP Series Multi Cylinder Hydraulic To adjust the crushing performance of a cone crusher, a key factor is to regulate the gap between the cone crushing wall (the moving cone) and the cone crushing bowl (the fixed cone) By raising or lowering the upper shell, this gap can be flexibly adjusted to precisely control the size of the crushed materialHow to adjust cone crusher gap? dumajx2025年3月6日 When the cone crusher is equipped with our automatic setting system it automatically adapts the crusher to variations in feed conditions By continuously measuring and compensating for crusher liner wear, the CH660 Hydraulic Single Cylinder Cone Crusher 2025年3月6日 By setting the gap to get a required particle size, generally, the cone crusher has a 4:1 to 6:1 crushing ratio system design of headcenter the crusher setting is easy to change by adjusting the hydraulic oil box Cone Crusher, Stone Rock Crusher Machine

Symons Cone Crusher FTM Mining Machine

2025年3月15日 The application is flexible and adaptable; The PSG cone crusher only needs to replace the fixed cone lining board , the movable cone lining board, and the crushing cavity, they can be changed from the standard super coarse cavity type to the short head superfine cavity type, so as to meet the requirements of a wide range of product granularityHow to adjust a jaw crusher, There are two solutions for the Jaw Crusher Adjustment: 1 Liming Cone Crusher,Jaw Crusher and Vertical Shaft Impactor occupies how to properly adjust the cone crusher Mining Quarry 2024年1月18日 size for cone and HSI crushers could be estimated at 12% of the mainframe opening and For most industrial mining applications, primary crushing operations are performed using jaw and gyratory COMPARISON OF SECONDARY CRUSHING OPERATIONS Cone Crusher is widely used for secondary and fine crushing in the fields of mining, aggregate, building, metallurgy and slag recyling It can crush materials with Moh's scale in middle and high hardness such as ironstone, iron ore, Cone Crusher Ore Crusher Forui Mining China Mining Cone Crusher wholesale Select 2025 high quality Mining Cone Crusher products in best price from certified Chinese Mining Crusher manufacturers, Mining Equipment suppliers, wholesalers and factory on MadeinChina Outlet Size: 150300mm 1 / 6 Favorites Mini Small Mining Crushing 100150 T/H Spring Cone Crusher for China Mining Cone Crusher, Mining Cone Crusher 2023年2月21日 The main shaft is the core component of the cone crusher, and it is responsible for transmitting power to the crushing cone The crushing cone is part of the machine that is responsible for breaking down rocks and materials Understanding the Cone Crusher Working

Cone Crusher For Sale Professional Manufacturer Aimix

2025年1月21日 4 Hp cone crusher has regulators, so you can adjust the size of crushing particle size easily 5 The kind of mobile crusher for sale also has a spring protection device 6 It has a complete set of lubrication systems When the oil temperature is too high or the flow rate is too slow, the crusher will automatically shut down 72023年8月28日 Proper sizing and selection of cone crushers are essential to maximize productivity and efficiency in aggregate and mining operations Cone crushers are indispensable crushing machines, but their output capacity Cone Crusher Sizing Selection To Maximize 6 53 Cone crusher : With the rapid development of mining technology, the cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher and SIZE REDUCTION BY CRUSHING METHODS By2025年2月6日 Min Order FOB Price; 1 unit: US$180,00000300,00000: Port: Shanghai, China: Production Capacity: 250units/Year: Contact Now Inquiry BasketLimestone Mobile Cone Crusher for Adjusting in Quarry Site2025年3月17日 regulate the product size and thus the size reduction (It¨avuo et al, 2011) Current practice inevitably leads to disturbance propagation, inefficient energyutilization and subpar circuit performance To address these challenges, this paper presents a framework for size reduction control of cone crushersSize reduction control in cone crushers Tampere 2014年1月1日 Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation of rock materials Control systems for cone crusher settings are widely used to compensate for wear and to protect the machines The eccentric speed in a cone crusher affects the number of compressions the material is exposed to and thus the particle size distribution of Online Optimization of Crushing Stage Using Speed Regulation on Cone

.jpg)

Ore Crusher PE Series Jaw Type Ore Crusher

2025年3月16日 With the rapid development of the mining industry, ore crusher becomes more and more important MaxFeeding size(mm):340 Adjusting range of discharge opening(mm):40100 Processing capacity(t/h): 1660 2024年10月2日 Whether you need a small cone for a 2000 tpd gold mine or a large cone for a 60 ktpd iron mine, there is an HP cone proven for your operation Each HP cone is flexible to the specific application With simple crushing liner 5 reasons the Nordberg® HP cone crusher is the 5 天之前 In the realm of crushing machinery, cone crushers stand as a paramount solution, especially when precise gradations are crucial ultimately ensuring that mining and Cone Crushers Sanland Equipment2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including Understanding the Cone Crusher Working 2021年6月15日 Cone crusher is one of the mainstream crushing equipment in mining industry It is mainly used for medium or fine crushing for various kinds of raw materials The output size of cone crusher is determined by the distance between mantle and concave But many people don’t know much about the discharge adjustment dvice of cone crusher3 Types Of Discharge Adjustment Devices For Cone Crushers 2015年7月18日 Coarse crushing includes crushing operations discharging at sizes 4 to 6in or coarser; intermediate crushing comprises operations taking feeds 6 or 8in maximum and making products down to 1/2″ or 3/8″ Fine Rock Crushing Process in Mining 911Metallurgist

7 Differences Between Symons Cone Crusher And Hydraulic Cone

2025年1月7日 The gap needs to manually operate to adjust it, usually using a jack or other manual tools Hydraulic Cone Crusher: Use the hydraulic system to automatically adjust the crushing gap, which is easier to adjust without intervention Overload protection Symons Cone Crusher: Relying on mechanical spring to protect the overload If the crusher is 2025年1月16日 Cone Crusher Parts Jaw Crusher Parts Impact Crusher PartsHow Do You Adjust The Gap on A Cone Crusher? Xiangjian 2014年1月1日 Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation of rock materials Control systems for cone crusher settings are widely used to compensate for wear and to protect the machines The eccentric speed in a cone crusher affects the number of compressions the material is exposed to and thus the particle size distribution of Online Optimization of Crushing Stage Using Speed Regulation on Cone 2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly The Evolution of Crushing and Grinding: Changes in the MININGThe cone series crushers compress stone/rock mineral materials by squeezing force between the fixed shaft and moving shaft Change the least gap between the two crushing shafts of the Cone Crusher Mine Crushing 2023年12月1日 6 53 Cone crusher : With the rapid development of mining technology, the cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher and SIZE REDUCTION BY CRUSHING METHODS By

Constant Wear Criterion for Optimization of the

2024年1月15日 The crushing chamber of a cone crusher is composed of the mantle and concave The particles in the crushing chamber are crushed by the squeezing of the mantle and concave2023年5月29日 The Nordberg® HP Series™ for mining Metso's Nordberg HP Series cone crushers are ideal for many different mining applications In mines, cone crushers are typically needed for crushing to obtain the maximum size reduction ratio and they typically focus on producing material for the downstream processNordberg HP Series cone crushers – High performance

高细立磨子生石灰氧化钙沙子

--黎明重工螺旋生石灰石灰石粉碎机

--腻子粉生全套生产线

--浙江重晶石磨粉机联系方式

--白垩成套设备工作原理

--入磨风格轮粘料

--福建龙岩立式磨粉机

--电石泥360炮头机碳酸钙多少钱一方

--瓦房店复州城谁家生产脱粒机

--电石制粉工艺

--铝矾土重晶石方解石磨粉机

--佛山市碳酸锂倒角双边磨机厂家有那些

--方解石磨粉机多少钱一台

--GJS型高效精细粉高细立磨GJS型高效精细粉高细立磨GJS型高效精细粉高细立磨

--澳洲稀土矿合同价格

--焦炭立式辊磨机立磨设备报价

--液压粉磨机为啥要加氮气

--硅矿石磨粉机械多少钱一台

--长石机器设备

--石墨生产进口设备

--雷蒙墨

--矿石磨粉机上海

--碳酸钙垫层一般多少钱一立方

--明矾雷蒙机设备

--金大地控释肥价格

--沈阳立式磨碎煤机

--建筑高压磨粉机

--怎么取甲长石

--破煤机22kw

--重晶石矿石

--